As we approach 2023 and beyond, the electronics industry is making significant strides in sustainability and eco-friendly practices. The demand for greener electronic devices is shaping the future of the market, and manufacturers are stepping up to the challenge by incorporating cutting-edge technologies and innovations in their supply chain. In this article, we will delve into the sustainable electronics manufacturing trends that are making a tangible impact on the environment and transforming the way consumer electronics are produced.

Key Takeaways

- Sustainable electronics manufacturing trends are revolutionizing the industry, bolstering environmental consciousness and eco-friendly practices.

- Manufacturers are redefining their supply chains to mitigate environmental impact and reduce emissions.

- Recycling initiatives play a crucial role in managing the lifecycle of electronic devices and preserving valuable resources.

- Electronics manufacturers are navigating the complex landscape of green incentives and government regulations to maintain a competitive edge while complying with sustainability mandates.

- Advancements in materials, technologies, and manufacturing services are propelling the industry towards a more eco-conscious future.

The Rise of Sustainable Manufacturing in Electronics: Paving the Way for 2030

Sustainable manufacturing in electronics is growing in significance, driven by consumer consciousness, environmental regulations, and market dynamics. Initiatives focusing on digital and green fabrication plants, renewable energy usage, and enhanced recycling solutions are propelling the industry toward a sustainable future. Stakeholders strive for manufacturing processes that mitigate environmental impact, prioritize transparency, and incorporate sustainable and green practices, all while maintaining efficiency and product quality.

Understanding the Core Principles of Sustainable Manufacturing

Sustainable lifecycle management plays a crucial role in achieving sustainable manufacturing. It encompasses the process of designing, producing, and disposing of products with minimal environmental impact while optimizing resource usage. Saving resources, reducing carbon footprints and emissions, as well as promoting sustainable disposal and eco-friendly materials, significantly contribute to a greener supply chain and increased sustainability in the electronics industry.

| Core Principles | Description |

|---|---|

| Reducing Environmental Footprint | Adopting processes that lower emissions and resource consumption |

| Transparency | Openly sharing information on sourcing, manufacturing, and environmental impacts |

| Sustainable Lifecycle Management | Ensuring eco-friendly practices throughout the entire product lifecycle, from design to disposal |

| Green Initiatives | Implementing environmental programs that help achieve net-zero targets and reduce waste |

The Role of Eco-Friendly Materials and Reduced Emissions in Electronics

The electronics industry is integrating eco-friendly materials and reducing emissions as a response to consumer demand and regulatory pressure. Innovations in PCB manufacturing using ‘print and plate’ techniques and the shift towards materials with lower embedded energy such as PragmatIC’s thin film alternatives are evidence of the industry’s commitment to sustainability. The use of gallium nitride over silicon and the embracement of low-toxicity chemicals exemplify movements to lower carbon footprints and achieve net-zero emissions.

“By adopting eco-friendly materials and processes, the electronics industry contributes to a sustainable global ecosystem while meeting the ever-growing consumer demand for innovative electronic devices.”

Companies that prioritize sustainability by reducing their environmental footprint, adopting eco-friendly materials, and committing to net-zero targets are paving the way for a greener future in the electronics industry.

Securing Public Relations Advantages Through Green Initiatives

Companies in the electronics manufacturing sector are realizing significant public relations benefits by promoting their green initiatives and sustainability efforts. Market leaders like Samsung are actively engaged in global take-back programs demonstrating corporate responsibility. Such initiatives not only contribute positively to public image but also align with growing global consciousness on environmental issues like global warming, thereby fostering greater public awareness and brand loyalty.

The following table highlights some of the most prominent green initiatives undertaken by leading electronics manufacturers:

| Company | Green Initiative | Benefits |

|---|---|---|

| Samsung | Global Take-Back Program | Reduces electronic waste and promotes recycling |

| Apple | 100% Renewable Energy Commitment | Minimizes carbon emissions and promotes clean energy usage |

| Sony | Recycling Centers | Facilitates responsible disposal and recycling of electronic products |

| LG | Zero Waste to Landfill | Eliminates waste output by recycling and repurposing materials |

In addition to contributing positively to their public image, companies that prioritize eco-friendly practices can also gain an advantage over their competitors by responding to the growing consumer demand for environmentally responsible products. As public awareness of global warming and other environmental concerns continues to grow, consumers increasingly seek brands that share their values and demonstrate a commitment to protecting the planet.

Investing in green initiatives not only helps businesses meet consumer expectations but also provides a competitive advantage in the rapidly changing landscape of the consumer electronics industry.

To secure a public relations advantage and stay relevant in today’s environmentally conscious market, electronics manufacturers need to:

- Implement eco-friendly practices throughout the supply chain

- Invest in innovative solutions to reduce waste and emissions

- Collaborate with industry partners to drive sector-wide sustainability efforts

- Communicate their commitment to sustainability effectively to consumers and stakeholders

By adeptly navigating the trend towards sustainability and embracing eco-friendly practices, electronics manufacturers can not only bolster their public image but also contribute to the global fight against climate change and environmental degradation.

Integrating Sustainable Lifecycle Management in Manufacturing Design

As the emphasis on sustainability grows within the electronics manufacturing industry, businesses are starting to embrace sustainable lifecycle management in their operations and manufacturing design processes. The adoption of design methodologies focusing on durability, longevity, and recycling not only enhances the lifespan of electronic devices but also minimizes electronic waste and increases overall sustainability.

To meet these goals, manufacturers are increasingly turning to innovative design solutions, such as:

- Flexible electronics

- Transient electronics

- Implantable biomedical devices using biomaterials

Designing for durability and longevity becomes an essential aspect of the manufacturing process, ultimately mitigating environmental impact in the long run. Improved product lifespans translate to fewer electronic devices ending up in landfills, directly contributing to the reduction of waste and promoting a sustainable future in the electronics industry.

“Adopting sustainable lifecycle management in manufacturing design is not only an environmentally responsible decision but also a strategically smart move in an eco-conscious market.”

Moreover, the ability to increase the recyclability of electronic components is a vital factor to consider. As a result, manufacturers need to implement proper recycling mechanisms and plan for the disposal of electronic waste. By incorporating recycling into the design process, businesses foster efficient and environmentally friendly practices that ultimately benefit both the industry and the planet.

In conclusion, integrating sustainable lifecycle management into manufacturing design is an essential step towards ensuring a greener, more environmentally responsible electronics industry today and in the years to come. As manufacturers focus on designing for durability, longevity, and recycling, they pave the way for a future where electronic devices have a lesser impact on our planet and promotes responsible consumption.

Adopting Low-Toxicity Chemicals and Low-Emission Processes

The pursuit of sustainability in electronics manufacturing has led to the widespread adoption of low-toxicity chemicals and low-emission processes. This shift aims to minimize the environmental risks associated with hazardous materials, such as lead, cadmium, and mercury.

One significant development has been the introduction of formaldehyde alternatives for green electroless plating. This eco-friendly innovation effectively reduces chemical waste while maintaining the quality and performance of the products. Similarly, the implementation of dry (plasma) etching has become a popular alternative to traditional wet etching. Dry etching offers long-term savings and a reduction in toxic waste in integrated circuit (IC) manufacturing.

These systemic changes in the manufacturing process signify a larger movement toward environmental conservation within the industry.

Several benefits come with adopting these sustainable practices. Let’s explore a few key advantages:

| Benefits of Low-Toxicity Chemicals | Benefits of Low-Emission Processes |

|---|---|

| Reduced environmental risks | Energy-efficient manufacturing |

| Decreased chemical waste | Long-term cost savings |

| Improved compliance with environmental regulations | Reduced carbon footprint |

| Enhanced public relations | Safer, cleaner work environments |

As the electronics industry continues to prioritize sustainability and eco-friendly manufacturing practices, adopting low-toxicity chemicals and low-emission processes not only benefits the environment but also contributes to the long-term success and competitiveness of businesses. With this trend gaining momentum, the future of electronics manufacturing holds promising developments in responsible, sustainable growth.

Driving Innovation: Additive Manufacturing and Its Environmental Benefits

Additive manufacturing has emerged as a game-changer in the electronics industry, revolutionizing production processes and contributing to the sustainable manufacturing market. By minimizing waste and streamlining resources, this innovative approach is transforming the way electronic devices are created. In this section, we will explore how additive manufacturing techniques help reduce waste, personalize products, lower emissions, and further develop the electronics sector.

Minimizing Waste with Additive Manufacturing Techniques

One of the most significant advantages of additive manufacturing is its ability to reduce waste in the production process. By selectively depositing materials layer by layer, this method can create complex components more efficiently than traditional subtractive methods, which involve etching away excess material. Two key techniques that have gained popularity in sustainable electronics manufacturing include:

- Print-and-plate: This method involves applying an ink-like material onto a plate and then curing it with ultraviolet light to create fine circuit patterns. Compared to traditional etching methods, print-and-plate results in less chemical waste and offers a more efficient production process.

- Laser-induced forward transfer (LIFT): LIFT employs a high-power laser to transfer material from a donor substrate to the desired location on a receiver substrate, enabling more precise layer-by-layer construction. By focusing the laser only on the areas that require deposition, LIFT ensures material is not wasted.

These techniques signify a radical shift in electronics production, ushering in a new era of sustainable manufacturing that conserves both materials and energy.

Personalizing Products while Lowering Emissions

As consumer demand for unique, customized products grows, additive manufacturing presents a prime opportunity to cater to this market while maintaining eco-friendly practices. Flexible electronics, which can be bent, folded, or stretched without losing functionality, play a significant role in enabling bespoke products.

“By using flexible electronics and leveraging renewable energy sources in manufacturing, companies can deliver tailor-made solutions with a significantly reduced environmental footprint.”

Flexible electronics offer enhanced adaptability in design and form factors, empowering manufacturers to create bespoke products that meet specific consumer requirements. Moreover, additive manufacturing processes generally consume less energy and generate fewer emissions than traditional manufacturing techniques. As such, adopting additive manufacturing in combination with renewable energy sources represents a win-win situation for businesses and the environment alike.

Ultimately, the integration of additive manufacturing and its potential environmental benefits paves the way for a more sustainable and innovative electronics sector. By embracing these cutting-edge techniques and harnessing renewable resources, companies can drive growth in this expanding market while contributing to the global effort to protect our planet.

Complying with Government Mandates and Green Investment Initiatives

The electronics manufacturing industry is currently navigating myriad new regulations and is actively seeking incentives to encourage eco-friendly practices. Government mandates for reduced emissions and cleaner production processes require agility and foresight from businesses, which must adapt to remain compliant.

Securing incentives for green manufacturing initiatives not only benefits companies financially, but also aligns with global efforts to tackle environmental challenges. Let’s take a closer look at some of the key regulations and incentives being implemented:

Navigating New Regulations and Securing Incentives for Eco-Friendly Practices

Recent environmental regulations impacting the electronics manufacturing industry include the Restriction of Hazardous Substances (RoHS) directives and the Waste Electrical and Electronic Equipment (WEEE) regulations. These policies aim to limit the environmental impact of electronic waste, ensuring the reuse and recycling of electronic products.

“Adhering to environmental regulations is not just about compliance; it’s about demonstrating corporate responsibility and mitigating the harmful effects of electronic waste on the environment.”

As a direct response to these regulatory shifts, numerous green investment initiatives have emerged to promote the adoption of eco-friendly practices in the industry. Some examples of these initiatives include:

- Energy efficiency grants offered by various government agencies

- Tax credits for investing in renewable energy technologies

- Initiatives by organizations like the Clean Electronics Production Network (CEPN) to develop sustainable manufacturing processes

These incentives, along with increasing consumer awareness and demand for eco-conscious products, have created a perfect storm for electronics manufacturers to prioritize sustainable practices and maintain a competitive edge in the market.

By integrating environmental regulations and actively participating in green investment initiatives, businesses in the electronics manufacturing sector can unlock opportunities for innovation and growth while contributing positively to global sustainability goals.

Influencing Change via Consumer Electronics: Public Awareness and Global Warming

Consumer electronics play a pivotal role in shaping public awareness about global warming and environmental conservation. With the growing concern over the environmental footprint of various products and services, companies are exhibiting increased awareness about their ecological impact. This has largely prompted the introduction of greener, more sustainable alternatives into the market, subsequently educating consumers and promoting environment-friendly living habits.

Market leaders are actively contributing to conversations on sustainability, primarily with the intention of influencing behaviors and driving consumer demand for environmentally conscious products. For instance, Apple has taken significant steps towards reducing their carbon footprint by using 100% recycled aluminum for their MacBook Air and Mac mini, and incorporating more recycled materials into the manufacturing of their iPhones.

“We’re committed to making our products without taking from the earth, and to become carbon-neutral across our entire business, including our manufacturing supply chain, by 2030.” – Apple

Here are some notable additions to the consumer electronics market, aimed at increasing public awareness about environmental conservation:

- Energy-efficient monitors and TVs – These screens consume less power compared to traditional displays, thereby reducing energy utilization.

- Solar-powered chargers and power banks – These devices harness renewable energy, paving the way for greener electronic accessories.

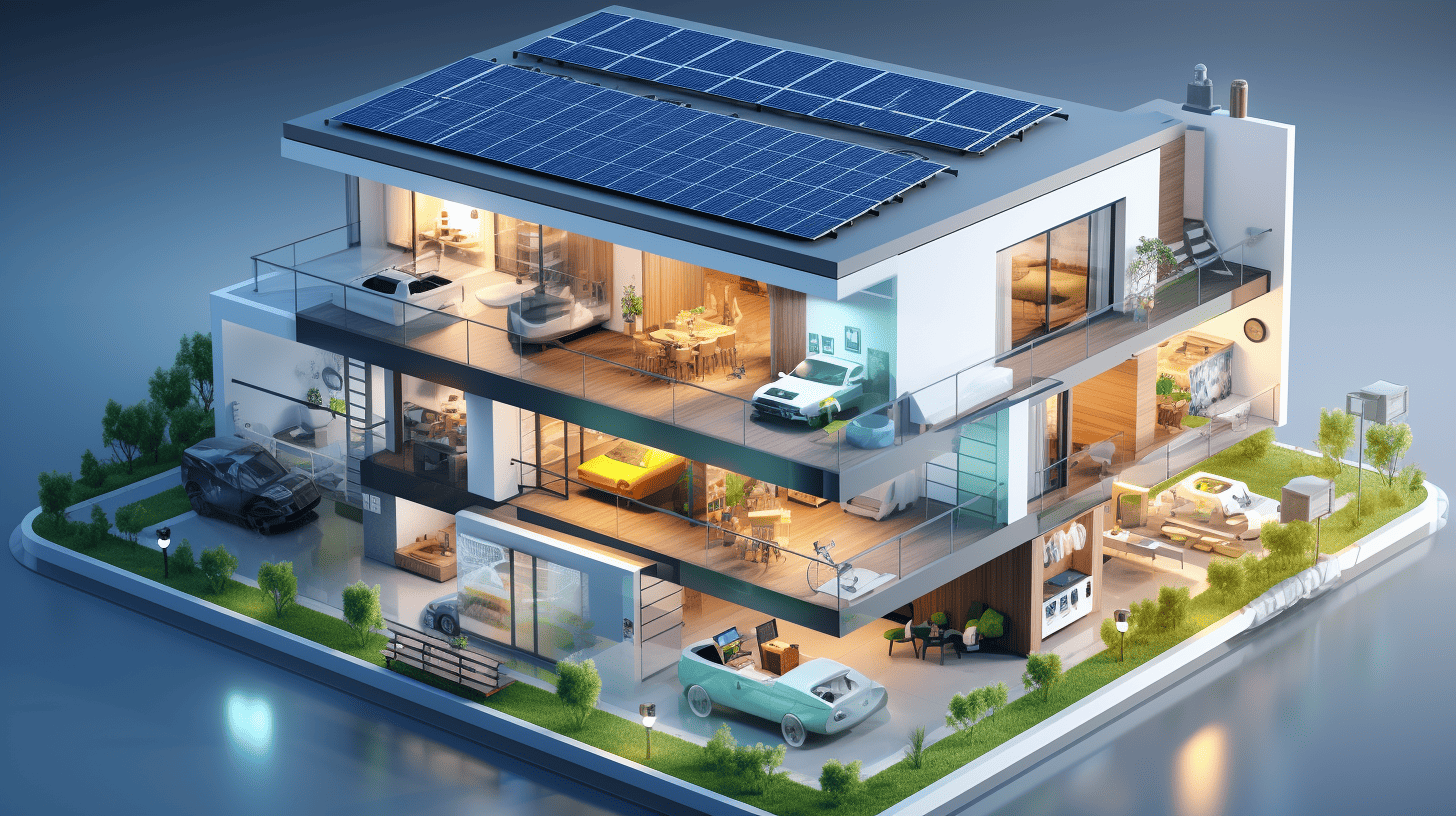

- Smart thermostats and home automation systems – They help manage energy consumption and reduce household carbon emissions.

To better understand the efforts made by various brands in promoting environmentally friendly consumer electronics, let’s take a look at a comparative table of some popular products:

| Product | Key Environment-friendly Feature | Brand |

|---|---|---|

| MacBook Air | 100% recycled aluminum enclosure | Apple |

| Galaxy S21 (Phantom Green) | Rechargeable battery with up to a 4,000 mAh capacity | Samsung |

| Nest Learning Thermostat | Energy-saving home automation | Google Nest |

| LG OLED55C1PUB | Energy-efficient OLED display | LG |

In conclusion, consumer electronics can significantly influence public awareness about global warming and environmental conservation. By focusing on producing sustainable, eco-friendly products and participating in educational campaigns, manufacturers can contribute positively to the planet’s well-being and inspire consumers to adopt greener lifestyles.

Embracing a Sustainable Future in Electronics Manufacturing

As we approach 2030, sustainable electronics manufacturing is paving the way for a greener, more responsible industry. With a focus on minimizing waste, reducing emissions, and incorporating eco-friendly practices, the industry is making significant strides in transforming the way electronic devices are produced. As part of this movement, electronics manufacturing services and innovative electronic devices are now designed with sustainability and environmental impact in mind.

From the adoption of low-toxicity chemicals to durable and sustainable product design, the industry works tirelessly to mitigate the environmental impact. Additive manufacturing is driving innovation and introducing customizable, greener solutions for consumers. These advancements are crucial in meeting new government regulations and securing incentives for green manufacturing practices. As the industry evolves, it is clear that the pursuit of a sustainable and environmentally friendly future is at the heart of its growth.

As consumer awareness of global warming and environmental responsibility grows, green electronics are becoming increasingly popular. These devices are designed not only to meet the evolving needs of environmentally conscious consumers but also to promote sustainable living habits on a global scale. In conclusion, with continuous innovation and a commitment to eco-friendly practices, the electronics manufacturing industry is poised to significantly contribute to a greener and more sustainable future.

FAQ on Sustainable Electronics Manufacturing Trends

Q: What is sustainable electronics manufacturing?

A: Sustainable electronics manufacturing focuses on producing electronic devices with minimal environmental impact, from the sourcing of materials to the disposal of the products.

Q: How does sustainability play a role in the electronics manufacturing market?

A: Sustainability has become a key consideration in the electronics manufacturing market, driving the demand for eco-friendly and energy-efficient production processes and products.

Q: What are the latest trends in electronics manufacturing with sustainability in mind?

A: The latest trends in electronics manufacturing include the use of sustainable materials, implementation of green manufacturing practices, and the development of technologies for electronic products with a reduced environmental footprint.

Q: How does sustainable electronics manufacturing contribute to reducing global greenhouse gas emissions?

A: Sustainable electronics manufacturing focuses on energy-efficient production processes and the use of eco-friendly materials, contributing to the reduction of global greenhouse gas emissions associated with electronic manufacturing facilities.

Q: What role do materials like artificial intelligence and internet of things play in sustainable electronics manufacturing?

A: Materials like artificial intelligence and internet of things are incorporated into sustainable electronics manufacturing to enhance energy efficiency, improve product design, and enable smart, sustainable technologies.

Q: What is the outlook for global sustainable electronics manufacturing by 2030?

A: By 2030, sustainable electronics manufacturing is expected to witness continued growth, driven by the increasing demand for sustainable technology and the adoption of eco-friendly practices in the electronics industry.

Q: How does the electronics industry address the demand for sustainable electronics products?

A: The electronics industry addresses the demand for sustainable electronics products by focusing on sustainable design, manufacturing processes, and the implementation of recycling and reusing strategies for electronic devices.

Q: What are some key innovations driving growth in sustainable electronics manufacturing?

A: Key innovations driving growth in sustainable electronics manufacturing include the development of new materials, advancements in electronic design for sustainability, and the establishment of manufacturing facilities with a reduced environmental impact.

Q: How does sustainability factor into the design and production of electronic devices?

A: Sustainability factors into the design and production of electronic devices through the incorporation of eco-friendly materials, energy-efficient technologies, and a focus on reducing the environmental footprint of manufacturing facilities.

Q: What are the key challenges and opportunities in the field of sustainable electronics manufacturing?

A: The key challenges in sustainable electronics manufacturing include addressing the environmental impact of electronic products, while the opportunities lie in driving innovation towards more sustainable and eco-friendly electronic technologies.

Source Links

- https://www.mckinsey.com/industries/automotive-and-assembly/our-insights/mapping-the-automotive-software-and-electronics-landscape-through-2030

- https://www.idtechex.com/en/research-report/sustainable-electronics-manufacturing-2023-2033/902

- https://www.linkedin.com/pulse/tablet-stands-market-trends-2023-2030

Leave a Reply