As a conscientious business owner, I’ve always been intrigued by the cost benefits of sustainable manufacturing. Through my own exploration and research, it quickly became apparent just how much going green with eco-friendly practices could ultimately save my business. It’s not just about reducing waste or conserving energy anymore – implementing sustainable manufacturing methods can create an energy-efficient business that effectively reduces its carbon footprint.

From using non-toxic sustainable materials to taking advantage of tax benefits and Plastic Neutral platform solutions, the possibilities for both financial benefits and improved environmental impact abound. Not only does it improve the bottom line and save money, but it also elevates a company’s reputation and market appeal, directly addressing the growing consumer demands for sustainable goods that protect our planet, and providing a safer work environment for employees.

Key Takeaways

- Adopting sustainable manufacturing methods reduces a company’s carbon footprint and overall environmental impact.

- Embracing energy-efficient practices can significantly improve a company’s bottom line and save money on operational costs.

- Meeting consumer demands for eco-friendly products strengthens a company’s reputation and market appeal.

- Creating a safer work environment contributes to employee satisfaction and wellbeing.

- Utilizing tax benefits and platforms like Plastic Neutral allow businesses to further their commitment to sustainability.

The Rise of Sustainable Manufacturing in a Cost-Conscious Business Environment

In the face of growing environmental awareness and consumer demand for eco-friendly products, the manufacturing industry is experiencing a shift towards sustainable manufacturing rise and practices. Companies are adopting cleaner and more efficient methods that not only showcase their commitment to climate change mitigation but also deliver significant cost savings in a cost-conscious business landscape.

One of the key drivers behind this transformation is the integration of lean manufacturing principles, which focus on minimizing waste and improving resource efficiency. Through the use of AI and the Internet of Things, lean manufacturing now includes environmental considerations, evolving into what is now known as green manufacturing initiatives.

Inc.com explains that sustainable practices like building efficiency and using fewer resources can lead to significant cost savings, with some companies saving millions annually.

These green manufacturing initiatives encompass a wide range of strategies, including energy efficiency, renewable energy, sustainable materials, waste reduction, and sustainable packaging. By implementing these practices, manufacturers can achieve lower resource costs and lower production costs, leading to increased revenues and a stronger competitive edge in the market.

In addition, embracing sustainable manufacturing can unlock a multitude of regulatory opportunities, such as access to tax breaks and financial incentives for environmentally responsible investments. Manufacturers also benefit from local manufacturing and sustainable sourcing, which further reduces their environmental impact and strengthens their supply chains.

Implementing green practices offer manufacturers a strategic advantage in buyer evaluations. Manufacturers that exhibit a commitment to environmentally responsible practices can find themselves attracting more clients and securing more contracts, contributing to their overall success and market competitiveness.

Ultimately, the rise of sustainable manufacturing provides a myriad of benefits – from enhancing brand reputation and customer loyalty to reducing waste and cutting costs. As businesses continue to navigate through economic uncertainties and mounting consumer expectations, adopting sustainable manufacturing practices represents not just a suitable choice, but a necessary one for future success.

Understanding Energy Efficiency and Its Role in Reducing Manufacturing Costs

Energy efficiency plays a pivotal role in the overall efforts to reduce manufacturing costs. By understanding its importance, businesses can make informed decisions that lead to long-term financial and environmental benefits. In this section, we’ll explore energy efficiency’s role in optimizing energy consumption, the financial advantages of renewable energy sources, and the financial impact of energy price fluctuations on traditional manufacturing.

Optimizing Energy Consumption for Long-Term Savings

Energy-efficient machinery and technological advancements significantly contribute to reducing manufacturing costs. By optimizing energy consumption through smart building automation, businesses can achieve long-term savings. For example, facilities that switch to LED lighting and replace outdated equipment with EnergyStar appliances can save substantially—implementation of green policies can yield millions in savings annually. Embracing energy-efficient technologies allows businesses to align their operations with environmental commitment while gaining a competitive edge.

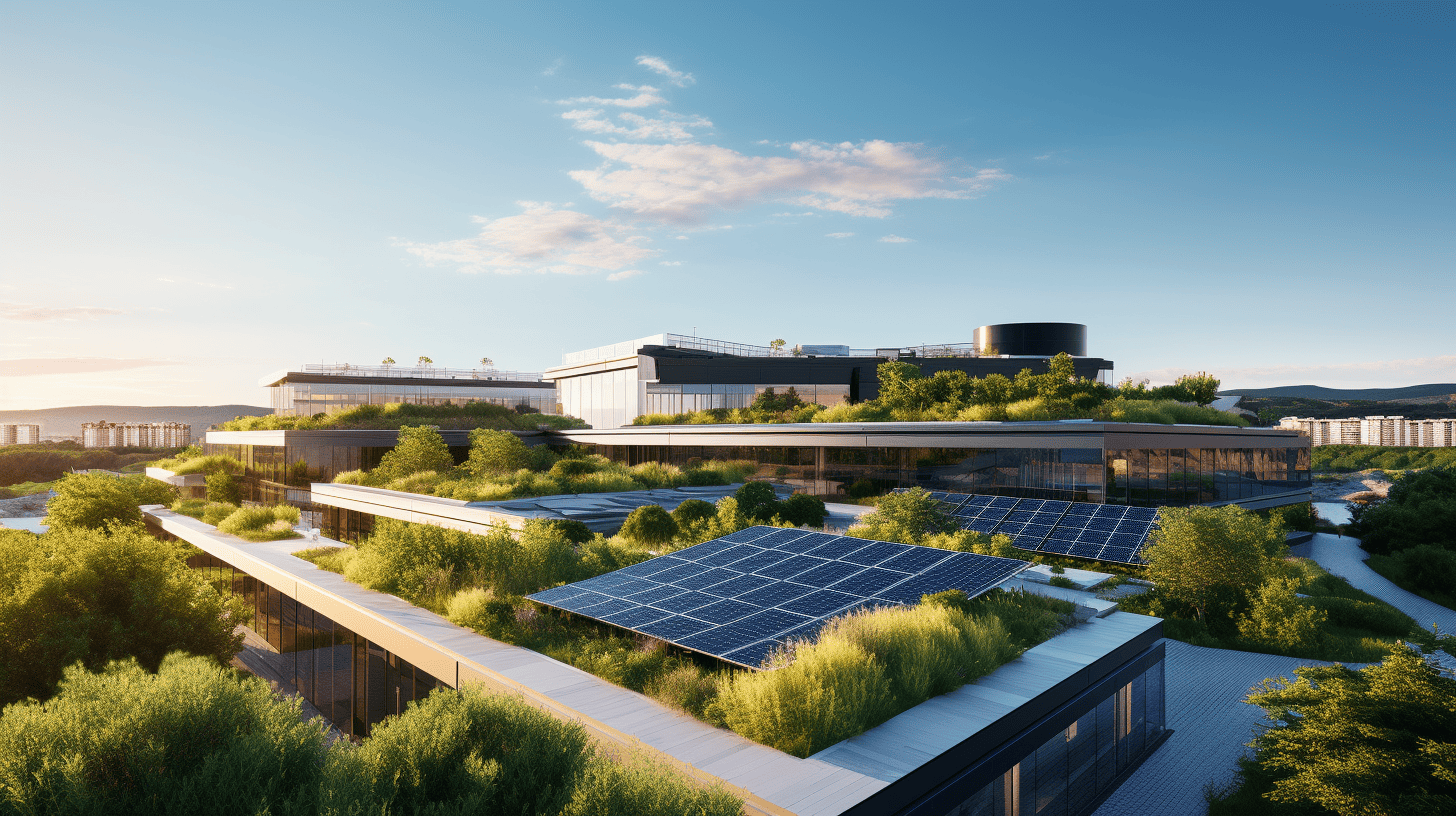

Renewable Energy Sources and Their Financial Advantages

Embracing renewable energy sources such as solar power, wind energy, and geothermal heating offers businesses considerable financial advantages while promoting a more sustainable future. As renewable energy becomes increasingly cost-effective, companies like Walmart and Anheuser-Busch InBev are committing to renewable systems. These energy sources can significantly cut manufacturing energy costs over time, with additional benefits like tax credits that can cover up to 30 percent of the investment. By choosing renewable energy, businesses achieve reduced energy costs, long-term stability, and demonstrate their environmental responsibility.

The Financial Impact of Energy Price Fluctuations on Traditional Manufacturing

Energy price fluctuations pose a significant financial impact on traditional manufacturing. According to the U.S. Energy Information Administration, energy prices have increased by an average of 15% in the past decade, directly influencing manufacturing overhead and profitability. To combat soaring energy costs, businesses must explore innovative solutions that minimize environmental impacts, maximize productivity, and ultimately lead to cost-saving measures.

Some effective strategies include employing energy-efficient technologies, implementing smart automation, and training staff in energy-saving protocols. By adopting these measures, businesses safeguard themselves against escalating energy costs and move closer to achieving their corporate sustainability goals.

Waste Reduction: Good for the Earth, Great for the Balance Sheet

Waste reduction and recycling are pivotal green manufacturing strategies that bring profound financial and environmental benefits. By reducing landfill waste and promoting resource conservation in the industry, companies can witness significant financial gains and sustainability improvements.

Integrating recycling practices into manufacturing routines results in reduced disposal costs, aiding businesses in their efforts to improve profit margins. Efficient resource utilization and cost savings can be realized through waste audits, which allow manufacturers to uncover recycling opportunities and minimize resource expenditures.

“Efficiency is doing better what is already being done.” – Peter Drucker

Resource conservation and waste reduction efforts, even small habitual changes, provide numerous environmental and financial benefits:

- Reduced landfill waste: By implementing recycling practices, materials are repurposed and kept out of landfills, reducing the negative impact on the environment.

- Decreased disposal costs: By recycling materials, manufacturers lower their waste disposal expenses and channel savings into their bottom line.

- Enhanced corporate image: Demonstrating a commitment to the environment, companies are recognized as responsible stewards, bolstering public perception and customer loyalty.

| Company | Waste Reduction Practice | Financial and Environmental Benefits |

|---|---|---|

| Intel | Implemented comprehensive recycling programs and waste audits. | Reduced hazardous waste by 30%, saving millions of dollars in disposal costs. |

| PepsiCo | Established a Global Sustainable Packaging Policy to minimize packaging waste. | Reduced waste generation by 11%, achieving a recycling rate of 93%. |

| Ford | Adopted innovative 3D-printing technology to repurpose waste materials into new car parts. | Reported annual savings of $2 million, while decreasing carbon emissions and landfill waste. |

As companies focus on embracing green manufacturing principles and waste reduction strategies, they pave their way to improved corporate profitability and a more sustainable future for the next generation. Such efforts provide clear evidence that responsible environmental stewardship and financial success can be achieved simultaneously.

Green Manufacturing and Its Positive Effect on Brand Value

Implementing green manufacturing practices allows companies to not only minimize their ecological footprint but also appeal to consumers’ preferences for eco-friendly products. This emerging awareness among consumers leads to increased customer loyalty and fosters the attraction of new customers, who value brands that prioritize environmental responsibility and corporate social responsibility.

How Sustainable Practices Increase Customer Loyalty and Attraction

Evidencing a commitment to sustainable practices can boost a brand’s reputation and ultimately strengthen public trust. Given the growing consumer demand for eco-friendly goods, businesses that invest in green manufacturing can experience a surge in popularity and attract new customers. Staying true to these principles can evoke appreciation from the current customer base, creating brand advocates who will spread the positive word about the company’s environmental commitments.

“Sustainability can no longer be viewed as a simple add-on. It’s an essential ingredient in building strong, responsible and future-facing brands that resonate with an ever more demanding and conscious consumer.”

- Responding to customer preferences for environmentally-friendly products

- Demonstrating a commitment to corporate social responsibility

- Fostering long-lasting relationships with customers through shared values

- Establishing credibility and trust in the market

Eco-Friendly Brands and Competitive Differentiation in the Market

In an increasingly competitive environment, leveraging sustainability as a unique selling point can help eco-friendly brands to differentiate themselves. Companies that exemplify a dedication to environmental responsibility are more likely to capture consumer interest and loyalty, secure an advantage over competitors, and attract new employees who desire to work for socially and environmentally conscious organizations.

Harvard.edu discusses how Nike’s use of sustainable materials like Flyleather and Flyknit has led to a reduction in production waste and costs.

Establishing a reputation for environmentally conscious branding and investing in sustainable business operations helps companies to solidify their standing as industry leaders in resorting to eco-friendly practices.

| Company | Green Initiative | Competitive Advantage |

|---|---|---|

| Patagonia | Sustainable sourcing and Regenerative Organic Certification | Positions the brand as a leader in environmental responsibility |

| Tesla | Electric vehicles and renewable energy solutions | Strong foothold in the sustainable transportation and energy industries |

| Unilever | Climate commitment and ambitious zero-emissions target | Attracts environmentally-conscious customers and employees |

As businesses embrace sustainable manufacturing practices, they become better equipped to meet growing consumer demands and benefit from increased customer loyalty, brand attraction, and competitive market positioning. Aligning with environmental responsibility is a strategic move that not only bolsters brand reputation but also promises long-term financial and operational gains.

Improving Sales and Access to New Markets Through Sustainability

As today’s market evolves and consumers become even more environmentally conscious, the importance of sustainable business strategies and eco-friendly manufacturing becomes apparent. By incorporating sustainability measures, manufacturers not only improve sales and access new markets, but also solidify their commitment to environmental responsibility and demonstrate their ability to evolve with changing consumer demands.

One of the main benefits of embracing sustainability is the ability to tap into growing market segments interested in sustainable products and environmentally friendly practices. By exploring new markets and implementing green initiatives in production, companies can better meet the demands of discerning consumers, driving increased sales and fostering brand loyalty.

Manufacturers that prioritize environmental sustainability not only meet these evolving consumer demands but are also positioned to tap into fresh revenue streams, ensuring long-term business viability and continued sales growth in the face of changing consumer preferences.

Market expansion becomes increasingly attainable for companies that invest in sustainability, as they are able to differentiate themselves from competitors and attract environmentally conscious consumers. This, in turn, can result in increased market share, brand recognition, and new business opportunities.

Some key benefits of sustainable business strategies include:

- Increased customer loyalty and attraction

- Innovative product offerings

- Enhanced brand reputation and public trust

- Improved market share and overall competitiveness

Ultimately, incorporating sustainable manufacturing practices to improve sales and access new markets is a strategic and forward-thinking approach to business growth. By investing in eco-friendly initiatives and continuously adapting to ever-changing consumer demands, manufacturers can ensure their businesses thrive, both financially and environmentally, for years to come.

Evaluating the Financial Gains from Lower Regulatory Compliance Costs

Companies that prioritize sustainable manufacturing can benefit from lower regulatory compliance costs, thanks to their alignment with the increasing environmental legislation. By meeting the industry standards and regulations, such as reducing carbon emissions and minimizing environmental impact, businesses can avoid legal implications and monetary fines.

In the pursuit of a greener future, sustainable manufacturing practices not only help save the planet but also prove advantageous in terms of corporate profitability.

The Intersection of Environmental Legislation and Corporate Profitability

Compliance with regulations and meeting sustainability goals serve as essential factors in maintaining and enhancing a company’s financial wellbeing. Failing to comply with environmental legislation can incur hefty fines and damage a company’s reputation, whereas adhering to these standards can foster the opposite.

By embracing eco-friendly protocols, companies can save on operational costs and capitalize on various incentives offered by government programs for environmental compliances. For example, tax breaks and grants for switching to renewable energy sources or investing in energy-efficient technologies can significantly ease the initial financial burden of adopting sustainable practices.

- Evaluating financial gains from sustainability initiatives

- Lowering regulatory compliance costs

- Strengthening corporate profitability

- Maintaining compliance with environmental regulations

- Capitalizing on incentives for environmental compliance

Thus, companies that invest in sustainable manufacturing not only project their commitment towards better environmental practices but also strengthen their financial footing in the market. By strategically assessing the costs related to regulatory compliance and cautiously implementing sustainable measures, businesses can stay ahead of the curve while positively contributing to a greener future.

| Benefits of Lower Regulatory Compliance Costs | Impact on Corporate Profitability |

|---|---|

| Avoidance of financial penalties | Increased revenue and cost savings |

| Eligibility for government incentives and grants | Ability to invest back into the company and enhance operations |

| Improved public perception and reputation | Attracts eco-conscious customers and partners |

| Adherence to environmental legislation | Avoidance of legal complications and barriers to market entry |

Leveraging Tax Incentives to Offset the Costs of Green Transition

Adopting sustainable technologies such as solar power, wind energy, and geothermal heating can be a significant financial undertaking for businesses. However, leveraging tax incentives and credits can help offset the costs of transitioning to greener practices. In this way, companies can make substantial investment savings while promoting renewable energy and reducing their carbon footprint.

Tax credits, a type of environmental investment, can cover up to 30% of the initial costs of implementing renewable energy technologies. These tax benefits help to alleviate the burden of green transition costs, making it more financially feasible for businesses to adopt eco-friendly practices. In turn, this helps to accelerate the shift towards a more sustainable economy and ultimately reduces the impact of climate change.

Businesses can receive tax credits up to 30 percent for eco-investments, translating to significant long-term savings and reinforcing their commitment to renewable energy and reduced reliance on non-sustainable sources.

Several categories of renewable energy technologies are eligible for tax incentives and credits, including:

- Solar power investments

- Wind energy projects

- Geothermal heating systems

Companies that invest in these technologies can enjoy a reduction in their tax liability, helping to offset the costs of greening their operations. It is essential for businesses to stay informed about the available incentives and ensure they meet the necessary requirements to take advantage of these financial benefits.

By investing in renewable energy technologies, businesses demonstrate their commitment to a sustainable future and showcase their environmental responsibility. These investments not only result in financial savings but also enhance companies’ reputation and market positioning as environmentally conscious organizations.

Overall, tax incentives play a crucial role in facilitating and incentivizing the green transition among businesses. By leveraging these financial benefits, companies can make significant strides in adopting sustainable practices, reducing their carbon footprint, and contributing to a cleaner, more sustainable economy for future generations.

The Advantage of Lower Production Costs and Improved Profit Margins with Sustainable Techniques

As businesses face growing pressure to implement eco-friendly practices and reduce environmental impacts, the synergy between lean manufacturing principles and green initiatives has guided companies toward significant improvements in operational efficiency and cost savings. This strategic approach delivers unparalleled value to consumers and shareholders while underscoring economic advantages of environmental consciousness.

How Adopting Lean and Green Manufacturing Lowers Expenses

By embracing sustainable techniques and integrating cutting-edge advancements such as AI and the Internet of Things, manufacturers continually strive to lower production costs while upholding high standards of quality. These innovative strategies create a more efficient operation and contribute to impressive cost reductions, ultimately leading to improved profit margins.

“Cost savings in green manufacturing are not just about reducing energy usage; they also involve optimizing resource usage, waste reduction, and emissions management.”

With the help of automation and data-driven decision-making, manufacturers can identify areas for improvement and implement cost-effective measures. The result is a lean and green system, characterized by successful waste management, sustainable resource allocation, and a minimized carbon footprint.

Streamlining Supply Chains with Sustainable Practices for Cost Efficiency

A well-coordinated and sustainable supply chain holds great potential for reducing operational expenses and enhancing manufacturing cost-efficiency. By prioritizing local sourcing, reshoring manufacturing, and partnering with companies focused on sustainability, businesses can reap multiple financial benefits, including:

- Reduced shipping costs through local manufacturing and shorter distribution routes

- Improved supplier evaluation scores, fostering long-term relationships and fostering collaborative efforts toward sustainability

- Better inventory management and lower carrying costs due to a more streamlined supply chain

These concerted efforts toward supply chain innovation result in decreased environmental impacts of manufacturing, emphasizing the value of strategic analysis and foresight in optimizing resource utilization and bolstering resilience within the industry.

As the advantages of sustainable techniques become increasingly evident, more and more companies are making meaningful strides to lower their production costs and achieve improved profit margins. By embracing lean and green manufacturing practices, organizations not only contribute to a more sustainable future, but also position themselves for greater financial gains and competitive market performance.

Conclusion on Lean Manufacturing

The benefits of sustainable manufacturing are undeniable, encompassing both environmental impact reduction and significant cost savings. As companies embrace sustainability and implement innovative business practices, they pave the way for a transformative green revolution within the manufacturing industry. By employing energy-efficient operations and focusing on waste reduction, manufacturers not only enhance their competitiveness but also help preserve our planet for future generations.

Broad adoption of sustainable practices across all aspects of the manufacturing process demonstrates a company’s commitment to social and environmental responsibility. It also enables manufacturers to make strategic business decisions that cater to growing consumer demands while adhering to increasingly strict regulations. As more businesses join the sustainability movement, the industry as a whole stands to gain immensely – from improved brand reputation to access to new markets and clients.

In conclusion, the sustainable manufacturing revolution has the potential to reshape the industry, creating a more balanced relationship between financial prosperity and environmental stewardship. By taking a proactive approach and prioritizing the adoption of eco-friendly practices, manufacturing companies can ensure a more resilient and thriving sector that delivers value to both consumers and our environment.

FAQ on Cost Benefits of Sustainable Manufacturing

Q: What is sustainable manufacturing?

A: Sustainable manufacturing is the creation of manufactured products through processes that minimize the use of resources, reduce energy consumption, and minimize greenhouse gas emissions, resulting in substantial financial and environmental benefits.

Q: What are the key benefits of sustainable manufacturing?

A: The key benefits of sustainable manufacturing include reducing costs, minimizing greenhouse gas emissions, conserving raw materials, and promoting environmentally and socially responsible practices in the manufacturing sector.

Q: How can sustainable manufacturing reduce costs for businesses?

A: Sustainable manufacturing can reduce costs for businesses by optimizing energy usage, minimizing waste, and improving efficiency in manufacturing operations, leading to cost savings in the long run.

Q: What are some best practices for implementing sustainable production in manufacturing?

A: Some best practices for implementing sustainable production in manufacturing include adopting eco-friendly manufacturing techniques, implementing efficient management systems, and focusing on minimizing environmental impact throughout the production process.

Q: How does sustainable manufacturing contribute to reducing greenhouse gas emissions?

A: Sustainable manufacturing contributes to reducing greenhouse gas emissions by using sustainable technologies and processes that minimize carbon footprint, thus mitigating the environmental impact of manufacturing operations.

Q: What are the environmental benefits of sustainable business practices in the manufacturing industry?

A: The environmental benefits of sustainable business practices in the manufacturing industry include conserving natural resources, reducing pollution, and promoting a more sustainable approach to the creation of manufactured products.

Q: How can businesses benefit financially from sustainable manufacturing?

A: Businesses can benefit financially from sustainable manufacturing through reduced operational costs, improved resource efficiency, and gaining a competitive edge in the market by resonating with socially conscious consumers.

Q: What role does sustainable manufacturing play in the overall sustainability of businesses?

A: Sustainable manufacturing plays a crucial role in the overall sustainability of businesses by fostering environmentally conscious production processes and promoting the adoption of sustainable business practices across the manufacturing sector.

Q: Can sustainable manufacturing contribute to the creation of a more socially responsible manufacturing sector?

A: Yes, sustainable manufacturing contributes to the creation of a more socially responsible manufacturing sector by prioritizing ethical and sustainable practices, thereby promoting positive social and environmental impact within the industry.

Q: What are the tangible benefits that businesses can experience from adopting sustainable manufacturing techniques?

A: Businesses can experience tangible benefits from adopting sustainable manufacturing techniques, including reduced waste, improved resource efficiency, and enhanced brand reputation as socially and environmentally responsible entities.

Leave a Reply