As the world grows more conscious of its environmental footprint, the realm of additive manufacturing is no exception. The use of eco-friendly 3D printing filaments and sustainable 3D materials is changing the game and paving the way for a greener industry. From biodegradable filaments to recycled plastic alternatives, we’re witnessing incredible 3D printing innovation in action. In this guide, we’ll explore the ins and outs of sustainable materials and practices that are leading us towards a circular economy.

Whether you’re just dipping your toes into the world of 3D printing or you’re a seasoned pro, it’s crucial to understand the environmental impact of our choices and adopt sustainable 3D printing practices. Let’s dive into the exciting world of eco-friendly filaments and discover how they’re shaping the future of additive manufacturing.

Key Takeaways:

- Eco-friendly 3D printing filaments reduce environmental impact and support a circular economy

- Biodegradable and recycled filaments offer sustainable alternatives to traditional plastics

- Plant-based innovations, like hemp and algae, bring renewable resources into the mix

- Composite filaments merge sustainable materials with unique aesthetic and functional properties

- Recycling and responsible material usage are key components of the green additive manufacturing movement

- Embracing sustainable practices today will shape the future of the 3D printing industry

Embracing the Green Revolution: The Rise of Eco-Friendly 3D Printing

The growing demand for sustainable additive manufacturing has made significant strides in meeting the expectations of both consumers and organizations. Eco-friendly 3D printing is becoming increasingly popular, as businesses and individuals aim to make environmentally conscious choices. The Green Revolution has triggered a shift towards a circular economy, supported by the widespread adoption of green material solutions and an increasing focus on minimizing the ecological footprint of production.

3DSourced suggests that while PLA filament is biodegradable, it requires proper disposal to live up to its eco-friendly potential. Commercial recycling or home composting is recommended for wasted PLA materials.

One of the most notable aspects of 3D printing technology is its inherent technological flexibility. Additive manufacturing can readily adapt and integrate sustainable innovations, thus promoting ongoing sustainable growth. As the industry continues to evolve, it demonstrates its commitment to environmental consciousness and the development of sustainable solutions. These innovations lend eco-friendly credibility to businesses embracing this new era of manufacturing.

“The Green Revolution in 3D printing is more than a trend; it is a necessity for ensuring the long-term sustainability and success of the industry.”

Recycling is a crucial element of the Green Revolution in 3D printing. Additive manufacturing is proving its commitment to sustainability through the increasing use of recycled 3D materials in production. By incorporating materials such as recycled PET, companies can reduce waste, contribute to the circular economy, and support a greener future.

- Transition to a Circular Economy

- Widespread Adoption of Environmentally Friendly Materials

- Reducing the Environmental Impact of Production

- Technological Flexibility to Integrate Sustainable Innovations

| Eco-Friendly 3D Printing Goals | Examples of Materials |

|---|---|

| Green Material Solutions | Biodegradable Filaments, Recycled PET |

| Recycled 3D Materials | RPET (Recycled Polyethylene Terephthalate), Recycled TPU (Thermoplastic Polyurethane) |

| Environmental Consciousness | Use of Bio-Based/Biodegradable Filaments, Recycling Programs, Energy Efficiency Initiatives |

In conclusion, combating climate change and meeting consumer demands for sustainable solutions requires a commitment to continued innovation. Eco-friendly 3D printing and sustainable additive manufacturing represent a solution with far-reaching implications for businesses and the planet alike. The Green Revolution is more than a trend; it is a necessity for ensuring the long-term sustainability and success of the industry.

Understanding Biodegradable Filaments: PLA and Its Eco-Friendly Companions

As 3D printing technology continues to evolve, the demand for sustainable materials is on the rise. Biodegradable filaments like PLA (polylactic acid) are becoming popular for their eco-friendly properties and versatility in various applications.

From Cornstarch to 3D Prints: The Journey of PLA Filaments

Derived from renewable resources such as cornstarch, cassava, and sugar beets, PLA has gained popularity for its sustainable appeal. The journey of PLA begins with extracting starch from these plants and fermenting it into lactic acid. This lactic acid then polymerizes into PLA, an environmentally considerate material.

Filamatrix advises that PLA is best for smaller projects due to its rapid breakdown. It’s a plant-based material ideal for businesses creating food-contact products, but it’s not heat-resistant and wears down with use.

PLA boasts superior biodegradability under industrial composting conditions, allowing it to decompose into harmless elements when properly disposed of. This feature sets it apart from other printing materials like ABS, which is notorious for contributing to environmental degradation. PLA filaments are highly versatile in their applications, often employed in producing prototypes, accessories, and a wide range of 3D printed items.

Biodegradable vs. Non-Biodegradable: Why It Matters

The distinction between biodegradable and non-biodegradable materials in 3D printing is crucial for environmental sustainability. PLA and other bio-based or biodegradable materials hold an advantage as they can be consumed by bacteria in industrial composting facilities, breaking down into their natural elements without leaving harmful residues.

Non-biodegradable plastics, such as ABS, are not broken down naturally and contribute to an increase in plastic waste in our environment. Therefore, a shift towards materials that decompose is an essential strategy for minimizing the ecological footprint of additive manufacturing and promoting a more sustainable future.

| Material | Biodegradable? | Derived From | Common Applications |

|---|---|---|---|

| PLA | Yes | Cornstarch, Cassava, Sugar beets | Prototypes, Accessories, Home Décor |

| ABS (Acrylonitrile Butadiene Styrene) | No | Petrochemicals | Functional Parts, Automotive Components, Toys |

| PETG (Polyethylene Terephthalate Glycol) | No | Petrochemicals | Containers, Mechanical Parts, Medical Equipment |

By integrating biodegradable filaments into the 3D printing landscape, we are taking a step forward in meeting the challenges of plastic waste and embracing an eco-friendly future for additive manufacturing. The use of these materials, such as PLA, serves as a symbol of progress towards a sustainable, green, and responsible 3D printing industry.

Finding the Balance: Economic Viability of Sustainable 3D Filaments

The economic feasibility of incorporating sustainable 3D filaments into production is crucial for widespread adoption. The use of such materials can lead to financial benefits through reduced costs on raw material procurement and waste management, enabling cost-effective 3D printing solutions. In addition, 3D printing’s capabilities for producing lightweight and optimized designs may result in further material and energy savings, presenting an eco-friendly process that is economically advantageous for several industries.

By examining the costs associated with traditional manufacturing and 3D printing, we can assess the benefits of embracing sustainable 3D filaments:

| Aspect | Traditional Manufacturing | 3D Printing with Sustainable Filaments |

|---|---|---|

| Raw Material Acquisition | High costs due to dependence on non-renewable resources | Reduced costs by sourcing eco-friendly and reusable materials |

| Waste Management | Expensive management of hazardous waste and disposal | Lower costs with reduced waste generation and recyclable materials |

| Energy Savings | High energy consumption due to extensive processes | Efficient energy usage with optimized designs and on-demand production |

| Optimized Designs | Constrained by traditional manufacturing techniques | Greater design freedom, reducing material usage and improving functionality |

“3D printing’s capabilities for producing lightweight and optimized designs may result in further material and energy savings, presenting an eco-friendly process that is economically advantageous.”

As we can see, the integration of sustainable 3D filaments into production processes has the potential to provide significant economic benefits. The increasing reliability and affordability of these materials will likely encourage more industries to make the transition to greener manufacturing methods.

- Emphasis on renewable resources: Sustainable 3D filaments derived from plant-based or recycled sources not only reduce environmental harm but also contribute to long-term cost savings by moving away from dependence on finite resources.

- Efficient resource management: By optimizing designs and eliminating unnecessary material usage, 3D printing allows for more efficient use of resources, lowering production costs and waste generation.

- Streamlined production processes: The adoption of eco-friendly 3D printing materials in on-demand manufacturing can lead to reduced warehousing and transportation costs, as products can be produced closer to end-users.

In conclusion, the economic viability of sustainable 3D filaments is a fundamental factor in encouraging businesses to adopt this eco-friendly solution. By creating a balance between environmental responsibility and financial feasibility, 3D printing with sustainable materials can lead to a greener and more cost-effective future for several industries.

Recycled Plastic Filaments: Turning Waste into Resource

3D printing has demonstrated its remarkable ability to transform plastic waste into valuable resources, harnessing the potential of recycled plastic filaments in the process. By utilizing materials such as recycled PET (RPET) from discarded plastic bottles and packaging, the additive manufacturing industry is actively promoting the core principles of the circular economy. Let’s review some inspiring case studies showcasing the successful application of recycled filaments in 3D printing.

Case Studies: Successful Use of Recycled Filaments in 3D Printing

One such impressive example is the Print Your City! initiative, which employed large-format 3D printers to convert plastic waste into an array of practical objects, such as public benches. This project not only reinforces the practical advantages of using recycled plastic filaments but also emphasizes the environmental and economic benefits achievable through such methods.

Additionally, a number of projects have harnessed recycled tire filaments, deploying them in inventive and useful applications, including robotic components and remote-controlled vehicles. This demonstrates the versatility and scope for innovation when embracing recycled filaments in 3D printing projects.

Moving towards closed-loop recycling systems can further advance waste reduction efforts. This approach involves recycling waste produced during the 3D printing process itself, enabling the creation of personalized spools of filament from leftover material. By enhancing recycling techniques and devoting resources to exploring new and innovative applications for recycled plastic filaments, the 3D printing industry stands well-positioned to address pressing environmental challenges and contribute to circular economy solutions.

In conclusion, by embracing recycled plastic filaments and exploring innovative applications of these materials, the 3D printing industry reinforces its commitment to environmental consciousness and the circular economy. As demonstrated by the various successful case studies, implementing recycled materials in 3D printing projects goes a long way in promoting sustainability, reducing waste, and achieving both economic and environmental benefits.

Plant-Based Innovations: Beyond Traditional Plastics

In our continuous pursuit of sustainable 3D printing, plant-based materials such as hemp, flax, and algae present unique and eco-friendly options beyond traditional plastics. By harnessing the renewable resources surrounding us, these innovative materials pave the way for a greener future in additive manufacturing.

The Role of Hemp, Flax, and Algae in 3D Printing

As new actors in the world of 3D printing, hemp PLA, algae PLA, and flax-based composites redefine the filament landscape. These biodegradable materials bank on the gifts of nature, tapping into the potential of renewable resources to create a more environmentally conscious approach to 3D printing.

- Hemp Filaments: Made from industrial hemp fibers, these filaments exhibit a reduced ecological footprint and showcase a unique appearance and texture reminiscent of raw wood.

- Flax Filaments: Derived from flax plant fibers, these filaments bear lightweight and robust features and demonstrate biodegradable properties for increased sustainability.

- Algae Filaments: Utilizing algae biomass as a chief component, these offerings bring both energy efficiency and carbon sequestration capabilities into the world of 3D printing.

Examining the Performance of Plant-Based Filaments

It’s essential to understand that the adoption of plant-based innovations in 3D printing is not just an eco-friendly strategy, but it also extends into the realm of functional applications. As such, the performance of these materials is regularly scrutinized to ensure they satisfy the requirements for various projects.

X3D recommends using dissolvable support materials like PVA and HIPS for easier removal and less environmental impact. Additionally, advancements in 3D printers allow for designs that don’t require supports, reducing material use.

Commitment to evaluating the versatile capabilities of plant-based filaments like hemp, flax, and algae underlines the industry’s devotion to maintaining both ecological sustainability and functional excellence.

| Material | Key Advantages | Common Applications |

|---|---|---|

| Hemp Filament | Low environmental impact, unique wood-like texture | Decorative items, architectural models, aesthetic prototypes |

| Flax Filament | Lightweight, strong, biodegradable | Automotive parts, drone components, sports equipment |

| Algae Filament | Energy efficiency, carbon sequestration | Packaging, sustainable product design, artistic creations |

The incorporation of plant-based filaments signifies an exciting era of sustainable 3D printing. By exploring materials such as hemp, flax, and algae, we broaden the scope of eco-friendly alternatives and reaffirm our commitment to a greener future in additive manufacturing.

Innovative Composite Filaments: Wood, Bamboo, and Beyond

As the sustainable 3D printing market expands, we are witnessing the arrival of innovative composite filaments. These unique materials blend PLA with natural components such as wood, bamboo, or waste materials from other industries, providing eco-friendly alternatives that boast distinctive aesthetic and functional qualities. Two prime examples of these composite filaments are WoodFill and BambooFill.

“WoodFill is formulated with 70% PLA and 30% wood fiber, while BambooFill combines bamboo with PLA.” -Anonymous

Integrating these natural elements into 3D printing filaments not only promotes environmental sustainability but also results in distinct visual and tactile properties. The following table illustrates the different characteristics of both WoodFill and BambooFill:

| Composite Filament | Material Blend | Aesthetic Appeal | Functional Properties |

|---|---|---|---|

| WoodFill | 70% PLA, 30% Wood Fiber | Wood-like appearance and texture | Dimensional stability and low shrinkage |

| BambooFill | PLA infused with Bamboo Fibers | Bamboo-like texture and unique surface finish | Lightweight and strong |

Both WoodFill and BambooFill make it possible for designers and artists to create sophisticated, attractive products while maintaining a reduced environmental impact. Additionally, these natural 3D printing materials serve as proof that sustainability and beauty can coexist, heralding a new age of biodegradable material innovation.

- WoodFill: A mix of PLA with 30% wood fiber offering a wood-like appearance and texture.

- BambooFill: A blend of PLA infused with bamboo fibers that provides a distinctive bamboo-like texture and surface finish.

Innovative composite filaments are revolutionizing the world of sustainable 3D printing by combining the world of natural materials with cutting-edge additive manufacturing technology. These environmentally-friendly filaments offer unparalleled aesthetic and functional properties, expanding the possibilities of eco-conscious design and inspiring new solutions for our planet’s future.

Recycling Your Prints: Best Practices for a Circular Economy

3D printing has opened the door to recycling print failures, support structures, and obsolete parts back into usable filaments. By repurposing these materials, not only do we reduce the environmental impact, but we also provide cost savings for 3D printing enthusiasts and professionals.

From Fails to Filament: Repurposing 3D Print Waste

Thanks to the advancements in filament extrusion technology, recycling 3D prints has become a reality. Innovative devices like Filabot and Recyclebot enable users to grind down plastic waste and extrude it into new filaments, facilitating the pursuit of a circular economy in the 3D printing world.

“Giving your print waste a second life not only reduces environmental impact but also turns waste and fails into valuable resources for new prints.”

Following circular economy best practices, several thermoplastics can be recycled effectively. Here are some methods to repurpose 3D print waste:

- Grind the waste material into small granules or powder.

- Heat the granules and extrude them into a filament using an extrusion device.

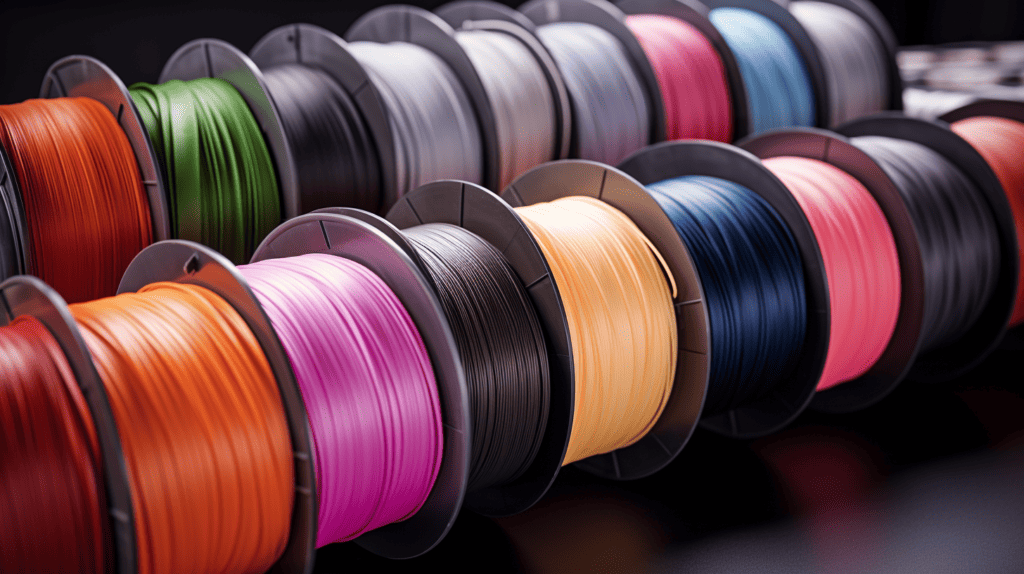

- Store the recycled filament on spools for future use or sell it as recycled material spools to other 3D printing enthusiasts.

To ensure successful recycling, it’s essential to maintain high-quality standards and preserve the functional and visual properties of the filament. Additionally, proper material separation and cleaning are crucial to avoiding contamination and maintaining color consistency.

It’s important to note that not all thermoplastics are equally suited for recycling. Polylactic acid (PLA) has limitations due to its lower thermal stability compared to other materials.

Beyond individual 3D printing enthusiasts, several companies lead the charge in repurposing 3D print waste at an industrial scale. Re-Filament, for example, focuses on recycling ABS and PETG waste, transforming it into high-quality filaments for further use in the additive manufacturing process.

Adopting recycling best practices and embracing circular economy principles contribute significantly to the development of sustainable 3D printing materials and processes, making a noticeable impact on both environmental and financial aspects.

3D Printing and Zero Waste: The Future of Additive Manufacturing

The concept of zero waste is increasingly becoming intertwined with the ethos of 3D printing. Advancements in biodegradable filaments and increased environmental consciousness among the Green 3D Printing Community signal a shift towards production methods that minimize waste.

The future of additive manufacturing is likely to be characterized by a continued emphasis on sustainability and responsible material usage, further aligning the industry with the global goal of reducing environmental impact. In this section, we’ll explore the factors driving this transition and how it’s shaping the future of 3D printing.

- Sustainable Practices: As more businesses adopt environmentally friendly practices, they are placing greater importance on using materials and processes that have a minimal ecological footprint. This includes using biodegradable filaments and optimizing print designs to reduce material waste.

- Biodegradable Filaments: Using materials like PLA and other bio-based alternatives reduces the amount of non-biodegradable waste that enters landfills, contributing to a more sustainable 3D printing industry.

- Environmental Consciousness: The desire to protect our planet and conserve resources is driving a growing interest in eco-friendly 3D printing solutions. This trend is inspired by widespread awareness of climate change and initiatives that promote sustainability.

As 3D printing continues to advance, it’s highly likely that we’ll witness even greater emphasis on sustainable practices and innovations in material technology. Here’s a glimpse of the progress made thus far:

| Material | Status |

|---|---|

| Polylactic Acid (PLA) | Widely used, biodegradable |

| Polyhydroxyalkanoates (PHA) | Emerging, biodegradable |

| Flax and Hemp fibers | Emerging, plant-based |

| Recycled PET (RPET) | Increasingly popular, recycled materials |

As the Future of Additive Manufacturing unfolds, it’s essential for businesses and consumers alike to embrace eco-friendly materials and processes. By doing so, we can reduce our environmental impact, create a greener 3D printing community, and contribute to a more sustainable world.

The Research Frontier: New Developments in Eco-Friendly Printing Materials

The world of sustainable 3D printing is observing a constant surge in the development of eco-friendly printing materials, with the research frontier focusing on the latest advancements in bioplastics and composite filaments. These innovative materials not only contribute to the reduction of reliance on petrochemicals, but they also extend the functional and environmental benefits of 3D printing filaments.

Latest Advancements in Bioplastics and Composite Filaments

Researchers and companies dedicated to sustainable 3D printing research are continuously exploring new developments in bioplastics. One notable example is the marrying of PLA with polyhydroxybutyrate (PHB), which adds heat resistance and durability to the final product. The innovation in composite filaments pertains to blending PLA with various natural fibers or industry waste materials to enhance specific properties of the final product.

“The research frontier in eco-friendly printing materials presents significant potential to transform the 3D printing industry, offering creative solutions to our ever-growing environmental concerns.”

Let’s delve deeper into some examples of composite filament innovation:

- Wood-PLA Composite Filament: By incorporating wood fibers into PLA, these composite filaments offer a natural wood-like appearance and can be sanded and stained like real wood, opening up a wide range of aesthetic possibilities.

- Metal-PLA Composite Filament: With a blend of metal powders and PLA, these filaments allow for lightweight 3D printed parts that have the appearance, weight, and thermal conductivity of their metal counterparts.

- Stone-PLA Composite Filament: By combining PLA with various stone powders, these filaments result in a unique and visually appealing texture that resembles natural stone materials.

These advancements in bioplastics and composite filaments open a new range of possibilities with a significant focus on sustainability, ensuring a brighter future for both the 3D printing industry and the environment. Continued exploration and research would only expand the scope of innovation for sustainable 3D printing materials.

3D Printing with a Purpose: Sustainable Solutions for Global Challenges

Addressing global sustainability challenges necessitates purpose-driven actions, and 3D printing is responding to this call by fostering collaborative efforts and engaging with local communities. The industry is exploring the use of greener materials while minimizing the carbon footprint of manufacturing processes. This shift is a critical component of the push towards sustainable solutions in response to global challenges.

Collaborations and Community Engagement for Green 3D Printing

Several organizations are taking initiative by implementing eco-friendly initiatives that go beyond the traditional approach to 3D printing. Projects range from transforming plastic waste into public amenities to developing accessible recycling methods for 3D print materials. Such collaborations are instrumental in driving change and making a tangible impact on global environmental challenges.

Innovative ideas are born from community engagement, including workshops, competitions, and group projects, which offer platforms for individuals and organizations to brainstorm sustainable solutions and share best practices. These interactions lead to a network of passionate individuals, each contributing to the green 3D printing movement by developing new materials and driving industrial efficiency.

“The only way to address sustainable development challenges is by thinking and acting together.” – Ban Ki-Moon, former UN Secretary-General

One such example is the collaboration between designers, engineers, researchers, and local governments. They team up to develop sustainable housing options, creating 3D printed buildings using environmentally friendly materials. These joint efforts help reduce construction waste and emissions, making significant strides towards combatting climate change.

- Partnerships with material manufacturers, research institutes, and recycling centers to develop and implement sustainable materials and recycling procedures.

- Community engagement events and initiatives that involve citizens in the process of creating and implementing sustainable 3D printing solutions.

- Collaborations with educational institutions to encourage sustainable practices within science, technology, engineering, and mathematics (STEM) programs.

These collaborative efforts and community engagement demonstrate that green 3D printing can be a potent tool in addressing global challenges. It inspires those in the 3D printing industry and beyond to join forces, working towards building a sustainable future together.

Conclusion on Eco-friendly 3d printing Filaments

As we reach the conclusion of our sustainable 3D printing journey, it is evident that eco-friendly filaments are making a significant impact in additive manufacturing. The adoption of responsible production practices and innovative materials is carving a future where 3D printing and environmental responsibility coexist harmoniously.

Throughout this guide, we have explored a multitude of sustainable 3D printing solutions, such as biodegradable materials like PLA, recycled filaments, and plant-based alternatives. These advancements push the boundaries of technology towards a circular, green future where we not only reduce our ecological footprint but also tackle pressing global challenges.

Together, it is crucial for the 3D printing community to embrace these sustainable techniques and work collaboratively to explore new eco-friendly solutions we can incorporate into our everyday practices. Let’s make the future of 3D printing synonymous with responsible material usage, environmental consciousness, and innovative green solutions.

FAQ on Sustainable 3d Printing

Q: What are sustainable 3D printing filaments?

A: Sustainable 3D printing filaments refer to materials that are environmentally friendly, typically made from biodegradable or recycled materials, and have a reduced impact on the environment compared to traditional 3D printing materials.

Q: How do sustainable 3D printing filaments contribute to reducing plastic waste?

A: Sustainable 3D printing filaments are often biodegradable or made from recycled materials, which helps in reducing plastic waste by providing eco-friendly alternatives to traditional plastic-based filaments.

Q: What are some common sustainable 3D printing materials?

A: Common sustainable 3D printing materials include PLA (polylactic acid), ABS (acrylonitrile butadiene styrene) made from biodegradable sources, PETG (polyethylene terephthalate glycol), and eco-friendly nylon filaments.

Q: How can I minimize the environmental impact of 3D printing?

A: You can minimize the environmental impact of 3D printing by using sustainable 3D printing filaments, optimizing printing parameters to reduce waste, and properly disposing of waste materials through composting or recycling.

Q: What are the advantages of using biodegradable 3D printer filaments?

A: Biodegradable 3D printer filaments offer the advantage of breaking down naturally over time, reducing the accumulation of non-biodegradable plastic waste and contributing to a more sustainable approach to 3D printing.

Q: Which 3D printing technologies are compatible with sustainable filaments?

A: Sustainable 3D printing filaments can be used with various 3D printing technologies such as FDM (Fused Deposition Modeling), providing eco-friendly options for filament-based 3D printing processes.

Q: What is the significance of using filament spools made from recycled materials?

A: Using filament spools made from recycled materials contributes to reducing the demand for new plastic production and promotes a circular economy by repurposing plastics that would otherwise end up as waste.

Q: How can I ensure proper adhesion when using sustainable 3D printing filaments?

A: Proper adhesion can be ensured by optimizing print bed temperature, using adhesion promoters suitable for sustainable filaments, and adjusting print settings to accommodate the filament’s specific properties.

Q: Are there filaments made from sustainable polymers suitable for contact with food?

A: Yes, there are sustainable 3D printing filaments, such as biopETG and PLA, that are considered safe for contact with food, providing a sustainable option for creating food-safe 3D printed items.

Q: Who can I contact for guidance on sustainable 3D printing materials and innovation?

A: You can contact experts in sustainable 3D printing materials and innovation, such as industry suppliers, eco-friendly filament manufacturers, or 3D printing community organizations, who are ready to help with guidance and information.

Leave a Reply